Saturday, January 18, 2014

Sabena Flight 548

Accident Snapshot:

Date: Wednesday, February 15, 1961

Location: Berg, Belgium (50° 56' 1" N, 4° 32' 9" E)

Persons/Fatalities: 72/72 +1 on the ground

Operator: Sabena Belgian World Airlines

Origin Airport: New York, Idlewild (JFK/KJFK)

Destination Airport: Brussels, Zaventem (BRU/EBBR)

Accident Aircraft:

Aircraft Type: Boeing 707-320

Registration: OO-SJB

First Flight: 1959

Total Airframe Hours: 3,038

Cycles: Unknown

Engines: 4 Pratt & Whitney JT4-9A Turbojet Engines

Profile view of Sabena-Belgian World Airlines Boeing 707-320 © Gregory Maxwell, 2014

Resources:

BCAA Final Accident Report - English

Aviation Safety Network Page

Wikipedia Page

Book about the Crash

Newsreel Footage of the Crash (59 sec)

BCAA Final Accident Report - English

Aviation Safety Network Page

Wikipedia Page

Book about the Crash

Newsreel Footage of the Crash (59 sec)

Accident Summary:

At the end of a New York/Brussels flight, which is normal in every respect, the aircraft is on a long final to runway 20 of the Brussels National Airport and receives clearance to land. Instead of landing the pilot, near the runway threshold, increases power and retracts the undercarriage. The aircraft gains some height and executes several circles in a left turn. During these evolutions the bank angle - while however decreasing several times for short periods - increases more and more until finally the aircraft is in a near vertical bank. The aircraft crashes and fire breaks out upon impact. The 11 crew members and 61 passengers are fatally injured. The aircraft is completely destroyed. One person on the ground is killed; another is severely injured.

Probable Cause:

Having done all possible reasonable investigations, the Commission concludes that the cause of the accident must be looked for in the physical failure of the flying controls.

However, while it was possible to advance certain hypothesis relative to these possible causes, it must remark that they generate certain objections and can therefore not be considered as entirely satisfactory. Only the physical failure of two systems can lead to a complete explanation, but leaves the door open to an arbitrary choice because there is not sufficient evidence to corroborate it.

ACCIDENT ANALYSIS:

Boeing 707 History with Sabena

The accident aircraft, OO-SJB, was the second of seven new Boeing 707-320 Intercontinental jets ordered by Sabena Belgian World Airlines. Aircraft c/n #17624 was the 92nd 707 to roll off the Renton line and was handed over to the company on the 15th of January 1960. Sister aircraft OO-SJA, delivered to the airline just a little over a month earlier on 12/04/59 launched the airline into the Jet-Age. Sabena wasted little time deploying the aircraft on its flagship Brussels-New York route and in the process the airline became continental Europe's first airline to offer trans-Atlantic jet service. Britain's BOAC had been operating regularly scheduled jet services between London and New York on the Comet 4 since October of 1958.

Sabena Maintenance Records

Following the test of the stabilizer control system investigators from the Civil Aviation Authority were left with more questions than answers and sought to examine the maintenance records of Sabena's Boeing 707-320 fleet to see if there were any previous incidences of faults involving the stabilizer system. Combing the records they were surprised to learn that there was in fact a history of faults involving the flight controls on Sabena's 707 fleet, but not with the stabilizer system but rather the aileron control system. OO-SJB in particular was found to have been affected numerous times by blocking or hard spots in the aileron control system which were documented in the aircraft's fault log.

Summary of Aileron Stiffness Reports on OO-SJB From 01/12/1960 to 02/14/1961

- 01/12/1960 Captain Libert - Flight LEO/E'VILLE

During descent LEO/E'VILLE, the aileron servo remained engaged. Right ailerons did not

function, after disconnecting A.P.

Note: These controls refunctioned after using the A.P. disconnect switch on the control wheel,

noted that the A.P. switch on the control pedestal was not completely in the "Off" position.

- Checked controls on ground and found "O.K."

- 5/11/1960 Captain Schreiden - Flight LEO/JOBURG

During descent at Jo'Burg - 260 IAS - 10,000 ft - Damper "On" - aileron very stiff, may be

slightly more to the right, become normal after very pronounced stiffness.

- Ailerons checked on ground - normal - no stiffness noted.

- 06/29/1960 - Captain Owen - Flight LEO/JOBURG

Flight controls (descent) at 12,000 ft, right aileron control completely locked. At 8,000 ft.

becomes normal.

- Proceed with complete aileron check and control of cables; nothing abnormal found.

06/29/1960 - Captain Smith - Flight LEO/BRUSSELS

At 31,000 ft tried control wheel to the left O.K., to the right was locked for a short instant to free

suddenly

- Controls tested on ground: nothing abnormal noted.

07/14/1960 - Captain Smith - Flight LEO/BRUSSELS

During the descent to Brussels, the aileron control is stiff in right turns only and without A.P.

engaged.

- Checked controls on ground: O.K. suppose icing.

- 08/10/1960 - Captain Jaumoulle - Flight LEO/BRUSSELS

At 39,000 ft. found aileron locked, right turn impossible. Freed itself at 2,000 ft. after 2 to 3

minutes in warm air.

- Checked control action on ground - O.K., point under observation.

- 08/24/1960 - Captain Gigot - Flight JOBURG/LEO

Stiffening of aileron control during descent.

- Probably ice on ailerons during descent.

- 09/17/1960 - Captain Jaumoulle - Flight BRUSSELS/JOBURG

At F.L. 330, right aileron locked, freed after slight force on control wheel. During descent to

E'VILLE the ailerons (left and right) are locked; freed by moderate force on wheel.

- Checked aileron system on ground: O.K., greased system.

- 11/02/1960 - Captain Schreiden - Flight JOBURG/LEO & ROME/BRUSSELS

Frozen ailerons did not move by wheel or trim - please check controls - after thawing, feeling

looser than normal.

- Checked controls on ground - nothing abnormal noted.

- 11/03/1960 - Captain Henquin - Flight ATHENS/TEHRAN

Ailerons and aileron trim frozen during descent to Athens and Tehran.

- See point T.R. 9 S.V.P.

- 11/04/1960 - Captain Henquin - Flight BEIRUT/ATHENS/BRUSSELS

Aileron and aileron trim frozen during descent.

- Problem under study - to follow.

- 11/09/1960 - Captain Jaumoulle - Flight LEO/JOBURG

After one hour of flight aileron trim locked (SAT - 55 C). Aileron trim freed during descent (SAT -

10 C). During descent, noted ailerons also locked; all normal with SAT +10 C.

- To be followed.

- 11/12/1960 - Captain Verpoorten - Flight GENEVA/BRUSSELS

Clear air T -62 C stiffening in the ailerons during turns to the right in climb. Same thing noted

during descent to Geneva after 33,000 ft. in left turn till final approach speed 160 indicated (idem

at Brussels).

- To be followed.

- 11/13/1960 - Captain Jaumoulle - Flight LEO/BRUSSELS

After 1 hour aileron trim blocked. Ailerons very stiff, mainly in case of left turn.

- 11/17/1960 - Flight NEW-YORK/BRUSSELS

For information, during climb, the left aileron control remained temporary locked. Idem during

descent.

- Under observation.

- 11/24/1960 - Captain De Keyser - Flight JOBUR/LEO/ROME

There seems to be hard spot in the aileron control, sometimes to the left sometimes to the right.

- During test: O.K., seems to be due to icing.

Examination of Aileron Seizures

Armed with the information from the trouble reports and after speaking to Sabena maintenance personnel the investigators were able to determine the cause of the aileron seizures was exposure to low temperature. The cold soaking of the aircraft at altitude led to the seizure of the aileron trim mechanism under certain conditions. Tests conducted by Boeing were successful in replicating the conditions described by pilots in the trouble reports. The blockage was able to be overcome by applying a force equal to 90 lbs on the control column. It is important to note that both the left and right aileron trim mechanisms on OO-SJB were removed and replaced during the aircraft overhaul that began on 01/11/1961. After the overhaul there were no further reports of aileron blockage or stiffness in the controls of OO-SJB leading up to the accident flight.

However the log did reveal abnormalities in the stabilizer trim system that were encountered during a test flight immediately following the overhaul before the aircraft was placed back into line service. The first incident occurred on the first test flight on 02/09/1961 during which the pilot indicated that the trim button had to be pushed harder than normal in order to activate.

A second test flight was conducted to confirm the fault, after which the pilot in command reported that the stabilizer's response was abnormal, particularly after trimming, nose down, slight nose-up impulses gave no result. Another incident on that same test flight was observed with the pilot noting:

"At the beginning of the flight - strong tendency of the aircraft to roll to the right - in level flight,

the two left wing spoilers are at the inch up."

"After descent, speed brakes out, at the moment of retraction there was a marked roll to the right -

did not reoccur afterwards."

"At the end of the flight, the tendency to roll to the right was considerably diminished."

Maintenance addressed the issue by replacing the stabilizer trim motor. Ground testing of the stabilizer, showed normal travel in both directions after the motor replacement and no further action was taken.

Between the aileron stiffness reports in the trouble log of OO-SJB and the test conducted on the stabilizer control system it became apparent to investigators that Sabena 548 had crashed as a result of a mechanical failure. Investigators also were able to surmise that the fault must have occurred sometime in the 60 seconds after the overshoot maneuver was initiated. While the fault mechanism that triggered the aircraft's erratic flight profile was not known the potential source had been isolated to three components: A fault in the stabilizer trim system, a seizure of the ailerons or a malfunction of the wing spoilers. It was also entirely possible that some combination of faults in two of the three systems combined to place the aircraft in an upset condition from which recovery was not possible.

Reviewing the information from the accident scene investigators knew the position of critical flight control surfaces.

- Stabilizer: 10 to 10.5 units nose up

- Elevator: Pointing Up

- Rudder: 20 degrees right deflection

- Ailerons: Inboard set for a right turn

Outboard probably neutral

- Spoilers: Left hand outboard: undetermined

Left hand inboard: probably retracted

Right hand inboard: extended (40 degrees)

Right hand outboard: undetermined

- Flaps: Up

Eyewitness reports and tracings from the flight recorder showed that the aircraft made only left hand turns and that the bank angle during these turns exceeded 60 degrees at times. However all the evidence from the crash scene indicates that the aircraft was in a right hand bank configuration. Despite the evidence from the crash scene the team could not with any degree of certainty prove that the position of the control surfaces as found was in fact the same position they maintained when the aircraft was in flight. But the appearance of the stabilizer near its maximum nose-up limit and the position of the elevators also in the up position was something that could not be easily dismissed.

As was previously established the stabilizer setting was well outside the position for a normal approach, given the aircraft's weight, flap configuration and airspeed. The aircraft would have had a tendency to pitch violently nose up with this stabilizer setting, a condition which would have only been amplified by application of any degree of elevator movement in the upwards direction. It would be counter-intuitive for a pilot to apply up elevator with such a high nose-up trim setting as the result given the aircraft's low airspeed and altitude would certainly be a stall from which recovery was impossible. So the question remains how did the aircraft get into this configuration and what aspects of the flight control surfaces failed during this critical phase of flight.

Probable Cause:

Having done all possible reasonable investigations, the Commission concludes that the cause of the accident must be looked for in the physical failure of the flying controls.

However, while it was possible to advance certain hypothesis relative to these possible causes, it must remark that they generate certain objections and can therefore not be considered as entirely satisfactory. Only the physical failure of two systems can lead to a complete explanation, but leaves the door open to an arbitrary choice because there is not sufficient evidence to corroborate it.

ACCIDENT ANALYSIS:

Boeing 707 History with Sabena

The accident aircraft, OO-SJB, was the second of seven new Boeing 707-320 Intercontinental jets ordered by Sabena Belgian World Airlines. Aircraft c/n #17624 was the 92nd 707 to roll off the Renton line and was handed over to the company on the 15th of January 1960. Sister aircraft OO-SJA, delivered to the airline just a little over a month earlier on 12/04/59 launched the airline into the Jet-Age. Sabena wasted little time deploying the aircraft on its flagship Brussels-New York route and in the process the airline became continental Europe's first airline to offer trans-Atlantic jet service. Britain's BOAC had been operating regularly scheduled jet services between London and New York on the Comet 4 since October of 1958.

Sabena-Belgian World Airlines Boeing 707-320 Poster Circa 1960

Pre-Departure

The mood in the terminal on Valentine's Day night at Idlewild International Airport on February 14, 1961 was festive as the 61 passengers and 11 crew prepared to board the sleek new 707 aircraft that would carry them to Brussels. Among the sixty-one people listed on the passenger manifest of flight 548 were the entire roster of the 1961 United States Figure Skating team which was on its way to the World Championships in Prague, Czechoslovakia. The U.S. Figure Skating Association contingent consisted of thirty-four athletes, coaches and support staff, which accounted for more than half of the passengers on board the flight. The remaining twenty-seven passengers were mostly American's hailing from every corner of the country from California to New Jersey and Texas to Michigan, as well as two Canadians and six Belgian nationals.

Around 6:00 pm the passengers stepped out of the cozy warmth of the terminal into the bitter cold winter night, walking across the snow dusted ramp to the buses that would deliver them to the waiting airplane. The boarding process unlike today was leisurely enough and without concern for security that the members of the U.S. Figure Skating team, bundled in their full winter coats, paused briefly on the rear aircraft boarding stairs for a series of pictures to capture the beginning of their grand adventure to Prague.

Around 6:00 pm the passengers stepped out of the cozy warmth of the terminal into the bitter cold winter night, walking across the snow dusted ramp to the buses that would deliver them to the waiting airplane. The boarding process unlike today was leisurely enough and without concern for security that the members of the U.S. Figure Skating team, bundled in their full winter coats, paused briefly on the rear aircraft boarding stairs for a series of pictures to capture the beginning of their grand adventure to Prague.

United States 1961 National Figure Skating Team Photo, Taken Prior to Departure of Sabena Flight 548

Flight History

Shortly after 7:00 pm eastern time the aircraft, with an all up weight of 263,452 lbs. and filled with 110,231 lbs. of fuel, taxied slowly to the threshold of runway 22R at Idlewild. OO-SJB at the moment it started its takeoff roll from New York had only been in service with Sabena for 13 months, having flown a little over 3,000 hours in the air. Departing into the cold night sky the 707-329 turned east and began its 7+ hour flight across the Atlantic Ocean to Belgium.

At 08:36 am Brussels time the aircraft cruising at 38,000 ft. reported over Dover, a few minutes later beginning its descent to flight level 200. In contact now with Brussels Center, the pilots received an updated weather report for Brussel-Zaventem Airport. The controller reported visibility of two miles, a ceiling of 19,000 ft and a temperature of 44 degrees F.

At 08:43 the 707-329 passed over Wulpen descending through 28,000 ft. Four minutes later the pilot reported Mackel descending through 19,000 ft.

At 08:48 the following message was transmitted by the crew on company frequency, "Estimating Brussels 08:54, aircraft technically O.K." The Boeing jet then overflew Dender passing through 13,000 ft at which time it was handed off to Brussels Approach Control.

The following is a transcript of the conversation between Sabena 548 referred to as, "JB" short for Juliet Bravo and Brussels Control up to the point of the accident as stated in the official accident report.

08:50:55

- Brussels Approach JB, we checked DU flight level 130 descending.

- Roger, JB, you (..?..) runway 20 for landing, the wind 330/2 kt, if you wish I'll take you for

final approach.

- Roger, thank you.

- What's your heading now?

- Heading 10 ... (hesitation) 110.

- Roger, take the heading of 080 to the left.

- Roger, 080 JB.

08:51:35

- JB, may start descend to 1,500 feet QFE 1024.5

- 1024.5, cleared to 1,500 feet.

08:52:10

- JB identified 13 N.M. WNW., continue on your heading and also your descend.

- Roger, JB.

- JB, present level and rate of descend?

- We have to reduce speed to make a quick descend, JB, we are now descending thousand feet a

minute, we expect to go in south as soon.

- What's your present level?

- 10,000 feet descending.

- In that case will you turn left on heading 020

- Roger 020.

- You are coming too close to the antenna, I will loose sight of you on the radar.

- Roger.

08:53:40

- Brussels JB, heading 020, flight level 7,500 now.

- Roger, understand, your position is 7 miles N.W., continue present heading.

- Roger.

08:55:40

- JB, flight level?

- 3,000 feet descending, still heading 020.

- OK, turn to the right on a heading 180.

- Roger, 180 to the right.

- Position is .... You are turning on long final, 13 miles north.

- Roger.

08:57:20

- Brussels JB, heading 180, height 1,500 feet.

- Roger, maintain 1,500 feet and turn to the right on a heading of 190.

- Roger JB, 190 to the right.

08:59:30

- Brussels JB, Hofstade 1,500 feet.

- OK can you continue on contact with the ground?

- OK Roger.

- You are cleared to land and call 118.6 from now on, you are 6 miles on final approach.

- All right, 118.6 - JB.

09:02:00

The intonation of voice was normal and does not lead one to suppose that, until that moment, there

was any particular worry on board, at least in the voice of the second pilot. However no call was

received on frequency 118.6 which was operating normally. The aircraft was called several times

on this frequency. The calls remained unanswered. Following this lack of contact, Brussels

Approach 124.5 again called the aircraft several times until 09:04 giving it amongst other things

clearance to land. These calls remained unanswered.

At 08:36 am Brussels time the aircraft cruising at 38,000 ft. reported over Dover, a few minutes later beginning its descent to flight level 200. In contact now with Brussels Center, the pilots received an updated weather report for Brussel-Zaventem Airport. The controller reported visibility of two miles, a ceiling of 19,000 ft and a temperature of 44 degrees F.

At 08:43 the 707-329 passed over Wulpen descending through 28,000 ft. Four minutes later the pilot reported Mackel descending through 19,000 ft.

At 08:48 the following message was transmitted by the crew on company frequency, "Estimating Brussels 08:54, aircraft technically O.K." The Boeing jet then overflew Dender passing through 13,000 ft at which time it was handed off to Brussels Approach Control.

The following is a transcript of the conversation between Sabena 548 referred to as, "JB" short for Juliet Bravo and Brussels Control up to the point of the accident as stated in the official accident report.

08:50:55

- Brussels Approach JB, we checked DU flight level 130 descending.

- Roger, JB, you (..?..) runway 20 for landing, the wind 330/2 kt, if you wish I'll take you for

final approach.

- Roger, thank you.

- What's your heading now?

- Heading 10 ... (hesitation) 110.

- Roger, take the heading of 080 to the left.

- Roger, 080 JB.

08:51:35

- JB, may start descend to 1,500 feet QFE 1024.5

- 1024.5, cleared to 1,500 feet.

08:52:10

- JB identified 13 N.M. WNW., continue on your heading and also your descend.

- Roger, JB.

- JB, present level and rate of descend?

- We have to reduce speed to make a quick descend, JB, we are now descending thousand feet a

minute, we expect to go in south as soon.

- What's your present level?

- 10,000 feet descending.

- In that case will you turn left on heading 020

- Roger 020.

- You are coming too close to the antenna, I will loose sight of you on the radar.

- Roger.

08:53:40

- Brussels JB, heading 020, flight level 7,500 now.

- Roger, understand, your position is 7 miles N.W., continue present heading.

- Roger.

08:55:40

- JB, flight level?

- 3,000 feet descending, still heading 020.

- OK, turn to the right on a heading 180.

- Roger, 180 to the right.

- Position is .... You are turning on long final, 13 miles north.

- Roger.

08:57:20

- Brussels JB, heading 180, height 1,500 feet.

- Roger, maintain 1,500 feet and turn to the right on a heading of 190.

- Roger JB, 190 to the right.

08:59:30

- Brussels JB, Hofstade 1,500 feet.

- OK can you continue on contact with the ground?

- OK Roger.

- You are cleared to land and call 118.6 from now on, you are 6 miles on final approach.

- All right, 118.6 - JB.

09:02:00

The intonation of voice was normal and does not lead one to suppose that, until that moment, there

was any particular worry on board, at least in the voice of the second pilot. However no call was

received on frequency 118.6 which was operating normally. The aircraft was called several times

on this frequency. The calls remained unanswered. Following this lack of contact, Brussels

Approach 124.5 again called the aircraft several times until 09:04 giving it amongst other things

clearance to land. These calls remained unanswered.

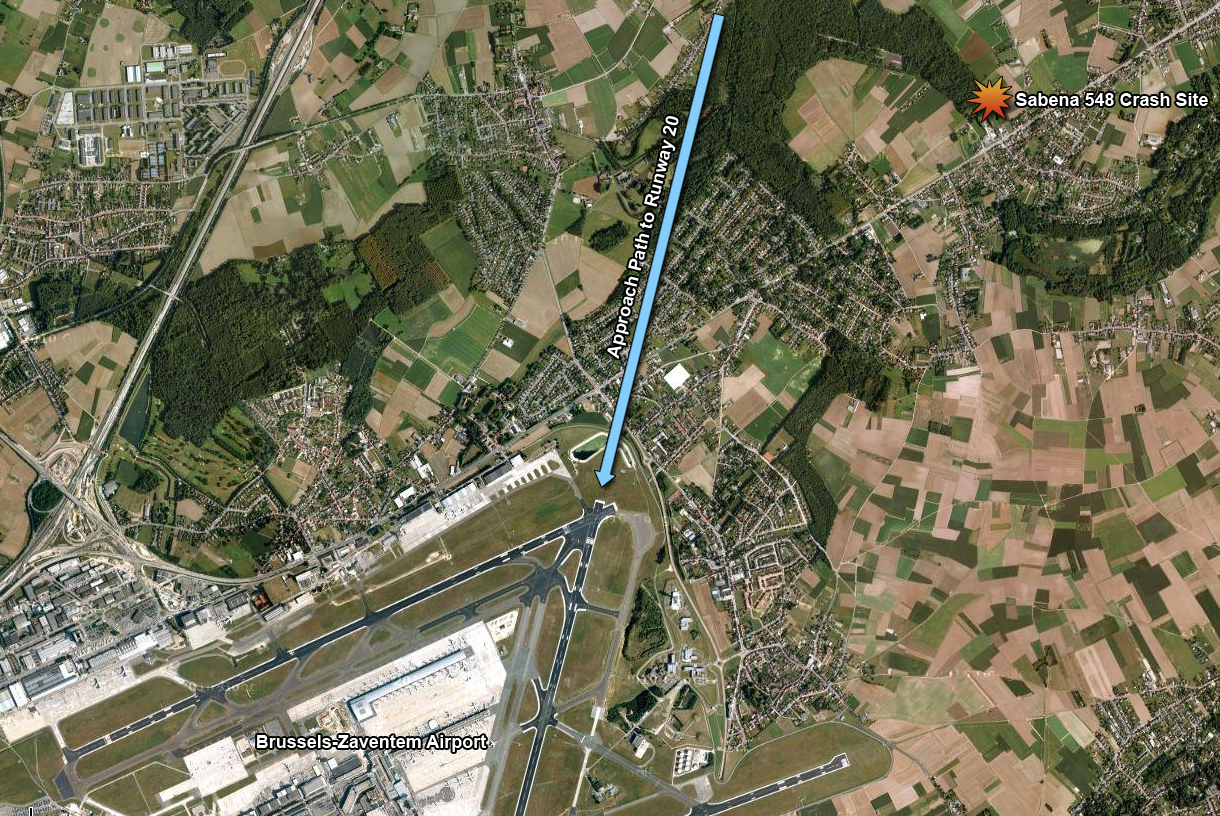

Map Depicting the Location of the Crash Site Relative to the Final Approach Path to Runway 20 at Brussels-Zaventem

The controllers would learn soon enough that the aircraft had in fact crashed into a field on the outskirts of the sleepy village of Berg a few miles northeast of Zaventem Airport. The aircraft impacted the ground with tremendous force, instantly killing all 72 passengers and crew on the aircraft as well as one person on the ground. The crash of OO-SJB marked the first crash of a Boeing 707 in commercial service and to this day remains the most tragic aviation accident in Belgium's history.

Flight Path Trajectory

Based on eyewitness reports including the tower personnel on duty, traces from the aircraft's flight recorder, ATC information and radio communications the Belgian Civil Aviation Authority (CAA) was able to reconstruct the final minutes of Sabena Flight 548. The aircraft's last position report came at Hofstade, approximately 5.5 nm from the threshold of runway 20 at Brussels-Zaventem Airport. The aircraft was established on the final approach with landing gear down descending through 1,500 feet.

Shortly thereafter Brussels Approach instructed "Juliet Bravo" to contact tower on 118.6, but the aircraft never did. According to personnel on duty in the Brussels tower the aircraft's altitude and attitude seemed normal as it approached the runway to land. Instead of landing OO-SJB overflew the runway threshold at an altitude of approximately 300 feet in a steep climb while banking to the left. At an estimated height of about 1,500 feet the aircraft was observed to have leveled off and a reduction in engine power was heard.

OO-SJB in the Final Desperate Moments of Flight with Bank Angle Approaching 90 Degrees © Gregory Maxwell, 2014

Next the aircraft entered into a series of steep left hand 360 degrees turns, maintaining a high bank angle throughout. During this time the aircraft's pitch was seen to oscillate between a nose up and nose down position and engine power was applied and the retarded several times. As the left hand turning maneuver continued the bank angle continued to increase until it reach almost 90 degrees according to several witnesses on the ground. Next the nose of the aircraft pitched over and the 707 crashed violently into the ground. Immediately following the aircraft's overshoot of the runway and as a result of its erratic flight maneuvers Air Traffic Control personnel in the tower alerted the fire fighting services of the Air Force and Brussels City who arrived quickly on the scene of the crash.

Newsreel Footage of the Crash

As fire fighters and other first responders arrived at the crash site, it became quickly apparent that the crash was likely not survivable due to the fragmentation of the airplane debris. Large parts of the aircraft structure had been completely destroyed by the impact and post crash fire, but it was still possible to reconstruct vital components of the flight controls on the wing and tail surfaces. From the aircraft remains the investigators were able to determine that the aircraft was intact prior to impact with the ground.

Control Surfaces Examination

Inboard Ailerons - The components were examined for damage and faults separate from those caused by the impact and fire and were found to be in a normal configuration. Examination of markings left on the structure allowed investigators to conclude that the inboard ailerons were in a right turn configuration. The left hand inboard aileron was in a 10 degree down position and the right hand surface was in a 14 degree up position. Examination of the cockpit revealed that the control pulleys beneath the captain's control column were locked in a left hand turn position while the copilot's controls were found to be in a right hand turn configuration. Importantly the cable that connects the two controls was found to be broken which explained why the copilot and captain's controls were in opposite positions.

Aileron Trim - The left hand trim mechanism was found in serviceable condition, outside of the damage sustained from the impact. The right hand trim mechanism had been exposed to fire and was jammed. The jamming of the mechanism was isolated to corrosion on the spring retainer and when examined by Boeing it was determined that the corrosion agent was a byproduct of the fuel fire and was not present before the impact.

Outboard Ailerons - The position of the ailerons at impact could not be determined with any degree of certainty based on the evidence available, however the position of the control rods of the lock-out mechanism indicated they must have been functioning and under normal conditions would have been in the neutral position. The left hand aileron was largely intact and no fault was found in the system absent the deformation caused by impact forces. The right hand aileron control system was badly damaged and the control rod was bent and the steel extremity was broken. Tests involving the control rod were undertaken to find out how and why it possibly failed. Results of these tests showed that their was an inherent weakness in the mechanism at the point of the attachment bolt to the bell crank, which caused the aileron control rod to fail due to impact forces and not a mechanical failure of the system.

Spoilers - Investigators had a difficult time determining the position of the spoilers at the moment of impact as the panels were all found to be in the retracted position when they examined the remains of the wing surfaces. However marks found on the control rods possibly indicated that the right hand inboard spoiler was extended about 40 degrees, which would therefore correspond to a right turn control input. Examination of the speed brake handle on the flight deck showed that the spoilers were retracted at impact. None of the system components examined by the investigators showed signs of failure prior to the crash.

Flaps - Examination of the wreckage showed the flaps were in the retracted position, which was confirmed by the position of the flap selector on the center pedestal in the cockpit.

Rudder and Vertical Stabilizer - The vertical fin was undamaged by fire and largely intact having been broken near the base by the force of the impact. Traces on the structure indicated the rudder was deflected 20 degrees to the right at impact which was cross referenced against the position of the rudder pedals, both were found to be in agreement. No abnormalities or flaws were found in the structure, hinges, tabs or balance panels. The control rods were also found to be correctly assembled and in good working order.

Elevator - The elevator was not exposed to fire and despite the impact was relatively undamaged. Examination of the structure showed no indication of failure prior to impact and the moveable control surfaces were concluded to have been in good working order prior to impact.

Inboard Ailerons - The components were examined for damage and faults separate from those caused by the impact and fire and were found to be in a normal configuration. Examination of markings left on the structure allowed investigators to conclude that the inboard ailerons were in a right turn configuration. The left hand inboard aileron was in a 10 degree down position and the right hand surface was in a 14 degree up position. Examination of the cockpit revealed that the control pulleys beneath the captain's control column were locked in a left hand turn position while the copilot's controls were found to be in a right hand turn configuration. Importantly the cable that connects the two controls was found to be broken which explained why the copilot and captain's controls were in opposite positions.

Aileron Trim - The left hand trim mechanism was found in serviceable condition, outside of the damage sustained from the impact. The right hand trim mechanism had been exposed to fire and was jammed. The jamming of the mechanism was isolated to corrosion on the spring retainer and when examined by Boeing it was determined that the corrosion agent was a byproduct of the fuel fire and was not present before the impact.

Outboard Ailerons - The position of the ailerons at impact could not be determined with any degree of certainty based on the evidence available, however the position of the control rods of the lock-out mechanism indicated they must have been functioning and under normal conditions would have been in the neutral position. The left hand aileron was largely intact and no fault was found in the system absent the deformation caused by impact forces. The right hand aileron control system was badly damaged and the control rod was bent and the steel extremity was broken. Tests involving the control rod were undertaken to find out how and why it possibly failed. Results of these tests showed that their was an inherent weakness in the mechanism at the point of the attachment bolt to the bell crank, which caused the aileron control rod to fail due to impact forces and not a mechanical failure of the system.

Spoilers - Investigators had a difficult time determining the position of the spoilers at the moment of impact as the panels were all found to be in the retracted position when they examined the remains of the wing surfaces. However marks found on the control rods possibly indicated that the right hand inboard spoiler was extended about 40 degrees, which would therefore correspond to a right turn control input. Examination of the speed brake handle on the flight deck showed that the spoilers were retracted at impact. None of the system components examined by the investigators showed signs of failure prior to the crash.

Flaps - Examination of the wreckage showed the flaps were in the retracted position, which was confirmed by the position of the flap selector on the center pedestal in the cockpit.

Rudder and Vertical Stabilizer - The vertical fin was undamaged by fire and largely intact having been broken near the base by the force of the impact. Traces on the structure indicated the rudder was deflected 20 degrees to the right at impact which was cross referenced against the position of the rudder pedals, both were found to be in agreement. No abnormalities or flaws were found in the structure, hinges, tabs or balance panels. The control rods were also found to be correctly assembled and in good working order.

Elevator - The elevator was not exposed to fire and despite the impact was relatively undamaged. Examination of the structure showed no indication of failure prior to impact and the moveable control surfaces were concluded to have been in good working order prior to impact.

First Responders Search Through the Wreckage of Sabena Flight 548

Stabilizer - Investigators observed that the stabilizer was in position of 10-10.5 units of noise-up trim which was very close to the maximum limit of 11 units. The position of the stabilizer was determined by examining traces on the structure as well as the position of the control screw and the position of the cables on the rear and front drums. Traces left by the needle on instrument indicator on the flight deck indicated a 8-8.5 unit nose up trim. The discrepancy between the traces on the structure and the instrument indicator was most likely due to the fact that the cable connecting the front drum and the indicator mechanism was severed at impact. The stabilizer control mechanism was closely examined for any electrical or mechanical failure and none was found. However an abnormal quantity of water condensation was found in the lower housing and the input shaft well for the electric actuator. In addition the locking nut of the input shaft of the electric trim actuator was found to have been excessively tightened and the locking washer had sheared. A piece of fiber was also found to be jammed between the rear drum and the cable. Chafing was also observed on the protective cover which had been caused by excessive rubbing of the cable on the housing. The stabilizer trim controls on the captain's and copilot's control column were removed and closely examined for any faults. Investigators determined that the thumb switch, cut-out switch, power and safety relays and the limit switch were in good working order. The cut-out switch on the panel appeared to indicate it was in the "On" postion however the pedestal had been deformed in the impact so a positive determination could not be made of the switch position.

Engines - All four Pratt & Whitney JT4-9A turbojet engines were removed and dismantled for closer examination. Investigators determined that the damage to the engines was consistent with that sustained from the impact and that all four engines were turning and functioning normally prior to the crash. The thrust reverser mechanisms on the number 1 and 4 engines were found intact and in the stowed position and all four thrust reverser levers controls in the cockpit were found to be in the stowed position. In addition the fuel controls on each engine were taken apart and no abnormality was noted. Engine instruments on the flight deck also indicated that all four engines were functioning normally with oil pressure, oil temperature and engine temperature readings all in the normal range. The instantaneous fuel flow indicators also showed 1,543 lbs/hr and 881 lbs/hr respectively. The engine oil quantities for all engines was also in the normal range. Examination of the fuel gauges indicated there was more than sufficient fuel remaining to feed all four engines.

Left Auxiliary 0 lbs

Main 1 3,500 lbs

Main 2 ------ (needle not present)

Main 3 4,400 lbs

Main 4 3,300 lbs

Right Auxiliary 0 lbs

Center 220 lbs

Total 11,420 lbs

Examination of the thrust levers on the center pedestal showed that all four engines were operating in the range of idle power. The thrust readings were determined by measuring the distance of the individual thrust levers from their respective rearward stops.

Electrical System - Auxiliary hydraulic pumps, lighting switch positions and the fact that the flight recorded was active indicate the engines were providing electric power and signified the presence of both AC and DC electrical current powering the various aircraft systems.

Radios - The VHF transceivers were badly damaged but the investigators were able to establish that they had indeed been set to the tower frequency of 118.6 as instructed by Brussels Approach control.

Autopilot - The "On, Off, damper" was found in the off position and the aileron synchro was found to be against the stop which indicated that the autopilot was disengaged at impact. The elevator and ruder servo motors were also found to be in good working order and the electric wiring didn't exhibit any signs of a fault. In addition the mach-trim switch was found in the "Off" position, indicating the system was disengaged at impact. The speed of the aircraft at impact was determined to be 177 knots as indicated by the KIFIS.

Hydraulic System - No system faults were found and investigators observed traces in the ventilators of the electric motors driving the auxiliary pumps that indicated they were operating at the moment of impact.

Landing Gear - The landing gear were found to be retracted based on the examination of the wreckage and the position of the landing gear arm on the flight deck panel.

The only abnormality discovered during the examination of the wreckage was the fault in the stabilizer trim mechanism, but what exactly could have caused this condition.

Engines - All four Pratt & Whitney JT4-9A turbojet engines were removed and dismantled for closer examination. Investigators determined that the damage to the engines was consistent with that sustained from the impact and that all four engines were turning and functioning normally prior to the crash. The thrust reverser mechanisms on the number 1 and 4 engines were found intact and in the stowed position and all four thrust reverser levers controls in the cockpit were found to be in the stowed position. In addition the fuel controls on each engine were taken apart and no abnormality was noted. Engine instruments on the flight deck also indicated that all four engines were functioning normally with oil pressure, oil temperature and engine temperature readings all in the normal range. The instantaneous fuel flow indicators also showed 1,543 lbs/hr and 881 lbs/hr respectively. The engine oil quantities for all engines was also in the normal range. Examination of the fuel gauges indicated there was more than sufficient fuel remaining to feed all four engines.

Left Auxiliary 0 lbs

Main 1 3,500 lbs

Main 2 ------ (needle not present)

Main 3 4,400 lbs

Main 4 3,300 lbs

Right Auxiliary 0 lbs

Center 220 lbs

Total 11,420 lbs

Examination of the thrust levers on the center pedestal showed that all four engines were operating in the range of idle power. The thrust readings were determined by measuring the distance of the individual thrust levers from their respective rearward stops.

Electrical System - Auxiliary hydraulic pumps, lighting switch positions and the fact that the flight recorded was active indicate the engines were providing electric power and signified the presence of both AC and DC electrical current powering the various aircraft systems.

Radios - The VHF transceivers were badly damaged but the investigators were able to establish that they had indeed been set to the tower frequency of 118.6 as instructed by Brussels Approach control.

Autopilot - The "On, Off, damper" was found in the off position and the aileron synchro was found to be against the stop which indicated that the autopilot was disengaged at impact. The elevator and ruder servo motors were also found to be in good working order and the electric wiring didn't exhibit any signs of a fault. In addition the mach-trim switch was found in the "Off" position, indicating the system was disengaged at impact. The speed of the aircraft at impact was determined to be 177 knots as indicated by the KIFIS.

Hydraulic System - No system faults were found and investigators observed traces in the ventilators of the electric motors driving the auxiliary pumps that indicated they were operating at the moment of impact.

Landing Gear - The landing gear were found to be retracted based on the examination of the wreckage and the position of the landing gear arm on the flight deck panel.

The only abnormality discovered during the examination of the wreckage was the fault in the stabilizer trim mechanism, but what exactly could have caused this condition.

After examining all the evidence at the crash site investigators were left with few clues outside of the anomalies in the stabilizer trim system. They could not explain why the flight crew would have trimmed the aircraft in such a manner that would place the mechanism so closed to the upper stop. Under normal flight conditions the stabilizer would never approach such a high nose up setting. To answers these questions the investigators turned to Boeing to help them understand the limitations of the system.

Stabilizer Tests

Tests were carried out to by investigators with the help of Boeing that tried to isolate certain fault conditions and insure the trim mechanism operated normally when taking into account the position of the stabilizer. Cold soak tests were conducted to simulate the atmospheric effects of the aircraft being at cruise altitude during its long trans-Atlantic flight. The results showed that water in enough quantity in the input shaft-well of the electric actuator could potentially cause the electric trim motor control to jam, which could also lead to excessive tightening of the locking nut as observed on the accident aircraft.

Further low temperature tests were conducted to determine the effects of contamination on the serviceability of the mechanism. Contamination was found to be a result of humidity in the air that penetrates the stabilizer control system during each flight at a time when the mechanism is no longer air tight and grease being forced into the top casing as a result of normal movement of the screw. Grease was found to have the potential to contaminate the lower casing by packing inside the mechanism's roller bearings. But could this contamination cause a fault in the rudder system that would leave the aircraft uncontrollable? To answer this question investigators had to better understand how the stabilizer's mechanical systems worked in particular how the primary and secondary brakes functioned to retard undesirable movement of the screw which was reversible.

The primary braking system utilized plates which when engaged came in contact with the screw shoulder on one side and the ratchet wheel on the other. The ratchet wheel's movement in the direction of the braking was prevented by a pair of dogs. When the stabilizer was moved in the direction opposite of the load, the dogs retract and only the outside loading must be overcome. When the nut moves due to the loads applied by the stabilizer movement, the screw will slip on the brake plates and the dogs will engage to limit the movement.

The secondary braking system employed a shoe brake, which when the screw was driven the shoes remained in the released or open position and when the screw moved as a result of the loading of the stabilizer the shoes was engaged to limit movement of the screw.

Tests were carried out to see to what degree both the primary and secondary brakes might be effected by contamination due to humidity, ice or grease or any combination of the three. Investigators observed that the secondary brake was prone to slipping when contaminated by grease as well as low temperature conditions. The brake was also vulnerable just after periods of cold soaking say during the descent phase of the flight as the system components were warmed by the hotter ambient air temperature in the lower atmosphere. Brakes which were not air tight were removed from an identical aircraft and under certain test conditions were made to slip. Not only were the brakes found to slip, but the rate of slip was observed to be very high. In some case the slip rate was twice the rotational speed of the electrical motor.

The primary braking system was also tested under the same conditions. While the efficiency of the system was reduced with the introduction of contamination of the same source, the effects were much less pronounced. The rate of slip was much lower, equating to only a fraction of a turn of the screw.

The influence of the fiber lodged between the rear drum and the cable due to the chafing of the cable on the protective cover could have in the investigators' opinion caused the disconnect clutch to function and render the electrical trim inoperative. However lab tests were not able to substantiate this theory.

Stabilizer Tests

Tests were carried out to by investigators with the help of Boeing that tried to isolate certain fault conditions and insure the trim mechanism operated normally when taking into account the position of the stabilizer. Cold soak tests were conducted to simulate the atmospheric effects of the aircraft being at cruise altitude during its long trans-Atlantic flight. The results showed that water in enough quantity in the input shaft-well of the electric actuator could potentially cause the electric trim motor control to jam, which could also lead to excessive tightening of the locking nut as observed on the accident aircraft.

Further low temperature tests were conducted to determine the effects of contamination on the serviceability of the mechanism. Contamination was found to be a result of humidity in the air that penetrates the stabilizer control system during each flight at a time when the mechanism is no longer air tight and grease being forced into the top casing as a result of normal movement of the screw. Grease was found to have the potential to contaminate the lower casing by packing inside the mechanism's roller bearings. But could this contamination cause a fault in the rudder system that would leave the aircraft uncontrollable? To answer this question investigators had to better understand how the stabilizer's mechanical systems worked in particular how the primary and secondary brakes functioned to retard undesirable movement of the screw which was reversible.

The primary braking system utilized plates which when engaged came in contact with the screw shoulder on one side and the ratchet wheel on the other. The ratchet wheel's movement in the direction of the braking was prevented by a pair of dogs. When the stabilizer was moved in the direction opposite of the load, the dogs retract and only the outside loading must be overcome. When the nut moves due to the loads applied by the stabilizer movement, the screw will slip on the brake plates and the dogs will engage to limit the movement.

The secondary braking system employed a shoe brake, which when the screw was driven the shoes remained in the released or open position and when the screw moved as a result of the loading of the stabilizer the shoes was engaged to limit movement of the screw.

Tests were carried out to see to what degree both the primary and secondary brakes might be effected by contamination due to humidity, ice or grease or any combination of the three. Investigators observed that the secondary brake was prone to slipping when contaminated by grease as well as low temperature conditions. The brake was also vulnerable just after periods of cold soaking say during the descent phase of the flight as the system components were warmed by the hotter ambient air temperature in the lower atmosphere. Brakes which were not air tight were removed from an identical aircraft and under certain test conditions were made to slip. Not only were the brakes found to slip, but the rate of slip was observed to be very high. In some case the slip rate was twice the rotational speed of the electrical motor.

The primary braking system was also tested under the same conditions. While the efficiency of the system was reduced with the introduction of contamination of the same source, the effects were much less pronounced. The rate of slip was much lower, equating to only a fraction of a turn of the screw.

The influence of the fiber lodged between the rear drum and the cable due to the chafing of the cable on the protective cover could have in the investigators' opinion caused the disconnect clutch to function and render the electrical trim inoperative. However lab tests were not able to substantiate this theory.

Following the test of the stabilizer control system investigators from the Civil Aviation Authority were left with more questions than answers and sought to examine the maintenance records of Sabena's Boeing 707-320 fleet to see if there were any previous incidences of faults involving the stabilizer system. Combing the records they were surprised to learn that there was in fact a history of faults involving the flight controls on Sabena's 707 fleet, but not with the stabilizer system but rather the aileron control system. OO-SJB in particular was found to have been affected numerous times by blocking or hard spots in the aileron control system which were documented in the aircraft's fault log.

Summary of Aileron Stiffness Reports on OO-SJB From 01/12/1960 to 02/14/1961

- 01/12/1960 Captain Libert - Flight LEO/E'VILLE

During descent LEO/E'VILLE, the aileron servo remained engaged. Right ailerons did not

function, after disconnecting A.P.

Note: These controls refunctioned after using the A.P. disconnect switch on the control wheel,

noted that the A.P. switch on the control pedestal was not completely in the "Off" position.

- Checked controls on ground and found "O.K."

- 5/11/1960 Captain Schreiden - Flight LEO/JOBURG

During descent at Jo'Burg - 260 IAS - 10,000 ft - Damper "On" - aileron very stiff, may be

slightly more to the right, become normal after very pronounced stiffness.

- Ailerons checked on ground - normal - no stiffness noted.

- 06/29/1960 - Captain Owen - Flight LEO/JOBURG

Flight controls (descent) at 12,000 ft, right aileron control completely locked. At 8,000 ft.

becomes normal.

- Proceed with complete aileron check and control of cables; nothing abnormal found.

06/29/1960 - Captain Smith - Flight LEO/BRUSSELS

At 31,000 ft tried control wheel to the left O.K., to the right was locked for a short instant to free

suddenly

- Controls tested on ground: nothing abnormal noted.

07/14/1960 - Captain Smith - Flight LEO/BRUSSELS

During the descent to Brussels, the aileron control is stiff in right turns only and without A.P.

engaged.

- Checked controls on ground: O.K. suppose icing.

- 08/10/1960 - Captain Jaumoulle - Flight LEO/BRUSSELS

At 39,000 ft. found aileron locked, right turn impossible. Freed itself at 2,000 ft. after 2 to 3

minutes in warm air.

- Checked control action on ground - O.K., point under observation.

- 08/24/1960 - Captain Gigot - Flight JOBURG/LEO

Stiffening of aileron control during descent.

- Probably ice on ailerons during descent.

- 09/17/1960 - Captain Jaumoulle - Flight BRUSSELS/JOBURG

At F.L. 330, right aileron locked, freed after slight force on control wheel. During descent to

E'VILLE the ailerons (left and right) are locked; freed by moderate force on wheel.

- Checked aileron system on ground: O.K., greased system.

- 11/02/1960 - Captain Schreiden - Flight JOBURG/LEO & ROME/BRUSSELS

Frozen ailerons did not move by wheel or trim - please check controls - after thawing, feeling

looser than normal.

- Checked controls on ground - nothing abnormal noted.

- 11/03/1960 - Captain Henquin - Flight ATHENS/TEHRAN

Ailerons and aileron trim frozen during descent to Athens and Tehran.

- See point T.R. 9 S.V.P.

- 11/04/1960 - Captain Henquin - Flight BEIRUT/ATHENS/BRUSSELS

Aileron and aileron trim frozen during descent.

- Problem under study - to follow.

- 11/09/1960 - Captain Jaumoulle - Flight LEO/JOBURG

After one hour of flight aileron trim locked (SAT - 55 C). Aileron trim freed during descent (SAT -

10 C). During descent, noted ailerons also locked; all normal with SAT +10 C.

- To be followed.

- 11/12/1960 - Captain Verpoorten - Flight GENEVA/BRUSSELS

Clear air T -62 C stiffening in the ailerons during turns to the right in climb. Same thing noted

during descent to Geneva after 33,000 ft. in left turn till final approach speed 160 indicated (idem

at Brussels).

- To be followed.

- 11/13/1960 - Captain Jaumoulle - Flight LEO/BRUSSELS

After 1 hour aileron trim blocked. Ailerons very stiff, mainly in case of left turn.

- 11/17/1960 - Flight NEW-YORK/BRUSSELS

For information, during climb, the left aileron control remained temporary locked. Idem during

descent.

- Under observation.

- 11/24/1960 - Captain De Keyser - Flight JOBUR/LEO/ROME

There seems to be hard spot in the aileron control, sometimes to the left sometimes to the right.

- During test: O.K., seems to be due to icing.

Examination of Aileron Seizures

Armed with the information from the trouble reports and after speaking to Sabena maintenance personnel the investigators were able to determine the cause of the aileron seizures was exposure to low temperature. The cold soaking of the aircraft at altitude led to the seizure of the aileron trim mechanism under certain conditions. Tests conducted by Boeing were successful in replicating the conditions described by pilots in the trouble reports. The blockage was able to be overcome by applying a force equal to 90 lbs on the control column. It is important to note that both the left and right aileron trim mechanisms on OO-SJB were removed and replaced during the aircraft overhaul that began on 01/11/1961. After the overhaul there were no further reports of aileron blockage or stiffness in the controls of OO-SJB leading up to the accident flight.

However the log did reveal abnormalities in the stabilizer trim system that were encountered during a test flight immediately following the overhaul before the aircraft was placed back into line service. The first incident occurred on the first test flight on 02/09/1961 during which the pilot indicated that the trim button had to be pushed harder than normal in order to activate.

A second test flight was conducted to confirm the fault, after which the pilot in command reported that the stabilizer's response was abnormal, particularly after trimming, nose down, slight nose-up impulses gave no result. Another incident on that same test flight was observed with the pilot noting:

"At the beginning of the flight - strong tendency of the aircraft to roll to the right - in level flight,

the two left wing spoilers are at the inch up."

"After descent, speed brakes out, at the moment of retraction there was a marked roll to the right -

did not reoccur afterwards."

"At the end of the flight, the tendency to roll to the right was considerably diminished."

Maintenance addressed the issue by replacing the stabilizer trim motor. Ground testing of the stabilizer, showed normal travel in both directions after the motor replacement and no further action was taken.

Between the aileron stiffness reports in the trouble log of OO-SJB and the test conducted on the stabilizer control system it became apparent to investigators that Sabena 548 had crashed as a result of a mechanical failure. Investigators also were able to surmise that the fault must have occurred sometime in the 60 seconds after the overshoot maneuver was initiated. While the fault mechanism that triggered the aircraft's erratic flight profile was not known the potential source had been isolated to three components: A fault in the stabilizer trim system, a seizure of the ailerons or a malfunction of the wing spoilers. It was also entirely possible that some combination of faults in two of the three systems combined to place the aircraft in an upset condition from which recovery was not possible.

Reviewing the information from the accident scene investigators knew the position of critical flight control surfaces.

- Stabilizer: 10 to 10.5 units nose up

- Elevator: Pointing Up

- Rudder: 20 degrees right deflection

- Ailerons: Inboard set for a right turn

Outboard probably neutral

- Spoilers: Left hand outboard: undetermined

Left hand inboard: probably retracted

Right hand inboard: extended (40 degrees)

Right hand outboard: undetermined

- Flaps: Up

Eyewitness reports and tracings from the flight recorder showed that the aircraft made only left hand turns and that the bank angle during these turns exceeded 60 degrees at times. However all the evidence from the crash scene indicates that the aircraft was in a right hand bank configuration. Despite the evidence from the crash scene the team could not with any degree of certainty prove that the position of the control surfaces as found was in fact the same position they maintained when the aircraft was in flight. But the appearance of the stabilizer near its maximum nose-up limit and the position of the elevators also in the up position was something that could not be easily dismissed.

As was previously established the stabilizer setting was well outside the position for a normal approach, given the aircraft's weight, flap configuration and airspeed. The aircraft would have had a tendency to pitch violently nose up with this stabilizer setting, a condition which would have only been amplified by application of any degree of elevator movement in the upwards direction. It would be counter-intuitive for a pilot to apply up elevator with such a high nose-up trim setting as the result given the aircraft's low airspeed and altitude would certainly be a stall from which recovery was impossible. So the question remains how did the aircraft get into this configuration and what aspects of the flight control surfaces failed during this critical phase of flight.

Maximum Travel of the Boeing 707-320 Horizontal Stabilizer © Gregory Maxwell, 2014

The position of the stabilizer can only be explained if:

1. One of the control systems of the stabilizer ran away.

2. There was an untimely slipping of the horizontal stabilizer due to unbalanced aerodynamic loads

acting upon it.

3. A failure of one of the other flight control surfaces required an increased action of the stabilizer

Accident Scenarios

1st Hypothesis: The position of the stabilizer is the result of a failure in the stabilizer trim control system.

Three independent systems can direct movement of stabilizer, the auto-pilot, the mach-trim system and the electric motor of the manual system. The auto-pilot aileron synchro switch was found in the off position on the flight deck and the system was disengaged. The mach-trim switch inside the KIFIS was in the open position, which eliminates this system. It is possible that the wiring to the stabilizer trim toggle switch on the pilot's control column experienced a short or became stuck allowing the stabilizer to runaway to the full nose up position unchecked.

1. One of the control systems of the stabilizer ran away.

2. There was an untimely slipping of the horizontal stabilizer due to unbalanced aerodynamic loads

acting upon it.

3. A failure of one of the other flight control surfaces required an increased action of the stabilizer

Accident Scenarios

1st Hypothesis: The position of the stabilizer is the result of a failure in the stabilizer trim control system.

Three independent systems can direct movement of stabilizer, the auto-pilot, the mach-trim system and the electric motor of the manual system. The auto-pilot aileron synchro switch was found in the off position on the flight deck and the system was disengaged. The mach-trim switch inside the KIFIS was in the open position, which eliminates this system. It is possible that the wiring to the stabilizer trim toggle switch on the pilot's control column experienced a short or became stuck allowing the stabilizer to runaway to the full nose up position unchecked.

The wiring in the control column was badly damaged by fire and it was impossible to discern the presence of electrical arcing or chafing of the wiring. Even if this did occur this event was foreseen in the emergency procedures by Boeing and can be easily rectified by operating the motor cutout switch on the center pedestal. It would have taken the stabilizer between 8 and 10 seconds to travel to the position of 10-10.5 units nose-up, and it is hard to imagine in that time that pilots would not have had sufficient time to operate the cut-out switch.

2nd Hypothesis: The position of the stabilizer is the result of a slipping stabilizer caused by a failure of the primary and secondary brakes.

As mentioned in Part 3 of this story uncontrolled slipping of the stabilizer under normal aerodynamic loading is prevented by the primary and secondary friction brakes. While lab tests did reveal that the secondary brake under certain conditions can experience high rates of slip, the primary system was found to have a very minimal slip rate in comparison. Investigators also had to concede that the efficiency of the two brakes under different aerodynamic loads was not known.

2nd Hypothesis: The position of the stabilizer is the result of a slipping stabilizer caused by a failure of the primary and secondary brakes.

As mentioned in Part 3 of this story uncontrolled slipping of the stabilizer under normal aerodynamic loading is prevented by the primary and secondary friction brakes. While lab tests did reveal that the secondary brake under certain conditions can experience high rates of slip, the primary system was found to have a very minimal slip rate in comparison. Investigators also had to concede that the efficiency of the two brakes under different aerodynamic loads was not known.

This could possibly explain why the crew lost control of the aircraft. But in order for this scenario to play out both the primary and secondary brakes would have had to fail simultaneously and the slipping of the primary brake would have to have been rapid which was contrary to the test results in the lab. If a rapid slipping of the stabilizer due to aerodynamic loads had occurred it is highly probable that the screw nut would have come into contact with the mechanical stop. When it actuality investigators found it was 1 to 2 turns from the stop when examined at the crash scene. This finding could have been the result of an attempt by the pilot to correct the out of trim condition, but this would require use of the manual trim system and investigators could find no evidence that the manual trim system had been activated leading up to the accident.

3rd Hypothesis: The position of the stabilizer was necessary to compensate for the failure of one of the other flight controls.

Under this scenario it assumed that the extreme nose up trim position of 10 units was a deliberate action of the pilots to counter the loss of one of the other flight control surfaces and find a position of equilibrium. It is a known fact that the effectiveness of the elevator decreases during a turn, causing the aircraft's nose to pitch down this is caused by the distance between the stabilizer and the center of gravity. In order to counteract the nose down movement the nose-up angle of the stabilizer must be increased.

3rd Hypothesis: The position of the stabilizer was necessary to compensate for the failure of one of the other flight controls.

Under this scenario it assumed that the extreme nose up trim position of 10 units was a deliberate action of the pilots to counter the loss of one of the other flight control surfaces and find a position of equilibrium. It is a known fact that the effectiveness of the elevator decreases during a turn, causing the aircraft's nose to pitch down this is caused by the distance between the stabilizer and the center of gravity. In order to counteract the nose down movement the nose-up angle of the stabilizer must be increased.

So it follows that a position of 10 units nose up trim could be necessary for a coordinated turn at a bank angle of 60 degrees at a speed between 120 and 155 knots with flaps fully extended. If the flaps were fully retracted the nose up trim would be reduced to no more than 7 units in a 60 degree turn near buffet speed. The investigative commission considered a failure of the stabilizer control system to be unlikely as in their estimation it could have been set to this position to aid in a steep low altitude turn brought about by the failure of one of the other control surfaces.

Inboard Ailerons

During high speed flight regimes with flaps retracted the outboard ailerons are inoperative leaving the inboard ailerons to control the aircraft's bank. As the trouble log indicated their were numerous write ups concerning sticking or seizing of the inboard ailerons in flight. The crash site revealed that the inboard ailerons were in a right turn configuration but whether the impact caused this deflection or they maintained that position in flight could not be definitively determined.

When examining the aileron trim cartridge investigators discovered a pinch point where jamming occurred in the tests due to insufficient clearance and corrosion. The corrosion deposits were found to be a byproduct of the fuel fire and were therefor not present prior to impact. The pinch point in the cartridge made lateral control beyond that position impossible. The position of the pinch would have allowed full travel of the aileron to the left and only limited movement passed neutral in the right hand turn direction. Investigators had a difficult time understanding why when the pilot realized he had limited roll control to the right that following the decision to go around that he did not maintain the aircraft in a wings level position and utilizing the rudder and other available control surfaces to control roll authority.

Lab test also showed that the jamming of the stabilizer trim cartridge could be overcome by applying a theoretical shear force of 105 lbs. on the control column which would cause the shear rivets on the connecting rod between the aileron trim cartridge and the aileron control to shear, thus clearing the jam. In actuality the lab tests performed by Boeing showed a shear force of 152 lbs. applied to the control column was needed to cause the rivets to shear, but when you consider both pilots applying force to the control column it seems entirely possible the crew could have produced the force necessary to clear the jam. But this theory ultimately does not pan out, as the critical rivets were found undamaged during the investigation of the wreckage.

Outboard Ailerons

If the conclusion is that the outer ailerons became blocked in a position just beyond neutral in either direction, then the extension of the flaps either partially or fully would serve to lock both the inboard and outboard ailerons. The only hint the pilot would have had to this developing condition would be a temporary displacement of the control wheel, which would probably have been slight enough that it would have gone unnoticed. If this condition was present then when the pilot initiated the go-around maneuver after overshooting the runway the action of raising the flaps would have had the following effect on the ailerons. First the inboard ailerons would react to the flap retraction by moving in the opposite direction and the amplitude of the movement would be several times the amount of offset from neutral of the outboard ailerons.

Inboard Ailerons

During high speed flight regimes with flaps retracted the outboard ailerons are inoperative leaving the inboard ailerons to control the aircraft's bank. As the trouble log indicated their were numerous write ups concerning sticking or seizing of the inboard ailerons in flight. The crash site revealed that the inboard ailerons were in a right turn configuration but whether the impact caused this deflection or they maintained that position in flight could not be definitively determined.

When examining the aileron trim cartridge investigators discovered a pinch point where jamming occurred in the tests due to insufficient clearance and corrosion. The corrosion deposits were found to be a byproduct of the fuel fire and were therefor not present prior to impact. The pinch point in the cartridge made lateral control beyond that position impossible. The position of the pinch would have allowed full travel of the aileron to the left and only limited movement passed neutral in the right hand turn direction. Investigators had a difficult time understanding why when the pilot realized he had limited roll control to the right that following the decision to go around that he did not maintain the aircraft in a wings level position and utilizing the rudder and other available control surfaces to control roll authority.

Lab test also showed that the jamming of the stabilizer trim cartridge could be overcome by applying a theoretical shear force of 105 lbs. on the control column which would cause the shear rivets on the connecting rod between the aileron trim cartridge and the aileron control to shear, thus clearing the jam. In actuality the lab tests performed by Boeing showed a shear force of 152 lbs. applied to the control column was needed to cause the rivets to shear, but when you consider both pilots applying force to the control column it seems entirely possible the crew could have produced the force necessary to clear the jam. But this theory ultimately does not pan out, as the critical rivets were found undamaged during the investigation of the wreckage.

Outboard Ailerons

If the conclusion is that the outer ailerons became blocked in a position just beyond neutral in either direction, then the extension of the flaps either partially or fully would serve to lock both the inboard and outboard ailerons. The only hint the pilot would have had to this developing condition would be a temporary displacement of the control wheel, which would probably have been slight enough that it would have gone unnoticed. If this condition was present then when the pilot initiated the go-around maneuver after overshooting the runway the action of raising the flaps would have had the following effect on the ailerons. First the inboard ailerons would react to the flap retraction by moving in the opposite direction and the amplitude of the movement would be several times the amount of offset from neutral of the outboard ailerons.

This movement could impart high stress loads onto the control system. These stresses had the potential to cause permanent distortion of the control elements or in the worst case failure of one or more of the aileron components. It is however possible to free the jammed inboard ailerons once the flaps reach the fully retracted position and if the movement did not cause permanent damage or distortion to the system. The linkage mechanism between the inboard and outboard ailerons and flaps makes it possible to setup a hard over position on the inboard ailerons if the outboard ailerons were locked before or after the extension of the flaps. This scenario is one possible explanation of the accident but the following facts would have to be ignored for this theory to have played out.

1. The commission did not uncover any evidence in the maintenance logs or trouble reports covering

Sabena's Boeing 707 fleet in which a seized outboard aileron was reported or found during regular

inspections.

2. There is no evidence in the wreckage at the crash scene that supports this hypothesis.

3. The inboard ailerons were found in a position for a right bank which, due to the presence of the

snubbers, could only with difficulty be explained by impact forces.

Spoilers

Upon examination of the spoilers at the crash scene investigators determined that the shear rivets on the mechanism between the spoilers and hydraulic valves were sheared on all four pairs of spoilers. Even more unusual the hydraulic bypass valve of the left hand outboard spoiler was found to be locked in the open position indicating a potential failure in the mechanism. If the rivets of the left outboard spoiler were sheared before impact, which couldn't be determined, then it would be possible for this set of spoilers to deflect to the full up position of 40 degrees. The position of the spoilers in this condition is dependent on the friction that exists in the system between the control valve, shear rivets and control rods. Over time the forces will cause the follow-up mechanism and the associated hydraulic valve to move out of alignment which will effect the up position of the spoiler when full deflection is commanded.

1. The commission did not uncover any evidence in the maintenance logs or trouble reports covering

Sabena's Boeing 707 fleet in which a seized outboard aileron was reported or found during regular

inspections.

2. There is no evidence in the wreckage at the crash scene that supports this hypothesis.

3. The inboard ailerons were found in a position for a right bank which, due to the presence of the

snubbers, could only with difficulty be explained by impact forces.

Spoilers

Upon examination of the spoilers at the crash scene investigators determined that the shear rivets on the mechanism between the spoilers and hydraulic valves were sheared on all four pairs of spoilers. Even more unusual the hydraulic bypass valve of the left hand outboard spoiler was found to be locked in the open position indicating a potential failure in the mechanism. If the rivets of the left outboard spoiler were sheared before impact, which couldn't be determined, then it would be possible for this set of spoilers to deflect to the full up position of 40 degrees. The position of the spoilers in this condition is dependent on the friction that exists in the system between the control valve, shear rivets and control rods. Over time the forces will cause the follow-up mechanism and the associated hydraulic valve to move out of alignment which will effect the up position of the spoiler when full deflection is commanded.

Normal Coordinated Left Turn © Gregory Maxwell, 2014

Induced Left Turn due to Fault in Left Outboard Spoiler © Gregory Maxwell, 2014

the pair of outboard spoilers were in fact jammed in the full up position of 40 degrees this would result in a roll rate of the aircraft of about 13 degrees per second at 150 knots. In order to overcome this induced roll the pilot would have to apply more than 20 degrees of movement to the control wheel in the opposite direction to neutralize the roll. Once the roll rate in the opposite direction of 20 degrees was reached the offending spoilers would collapse resulting in a roll in the opposite direction of around 4 degrees per second with flaps up and the aid of spoilers on the opposing wing. Without spoilers the roll rate would be around 2 degrees.

Normally a fault in any one of the four spoilers could be corrected by the pilot by activating the corresponding spoiler bypass switch. However the malfunctioning spoiler can't be succesfully bypassed if the bypass valve for that spoiler is stuck in the open position. Diagnosing the failure would be very difficult for the crew given the window of time and the fact that from their position in the cockpit they would not have been able to see the spoilers to know which one was not functioning properly.

Normally a fault in any one of the four spoilers could be corrected by the pilot by activating the corresponding spoiler bypass switch. However the malfunctioning spoiler can't be succesfully bypassed if the bypass valve for that spoiler is stuck in the open position. Diagnosing the failure would be very difficult for the crew given the window of time and the fact that from their position in the cockpit they would not have been able to see the spoilers to know which one was not functioning properly.